How to Extend the lifetime of Marine Engines

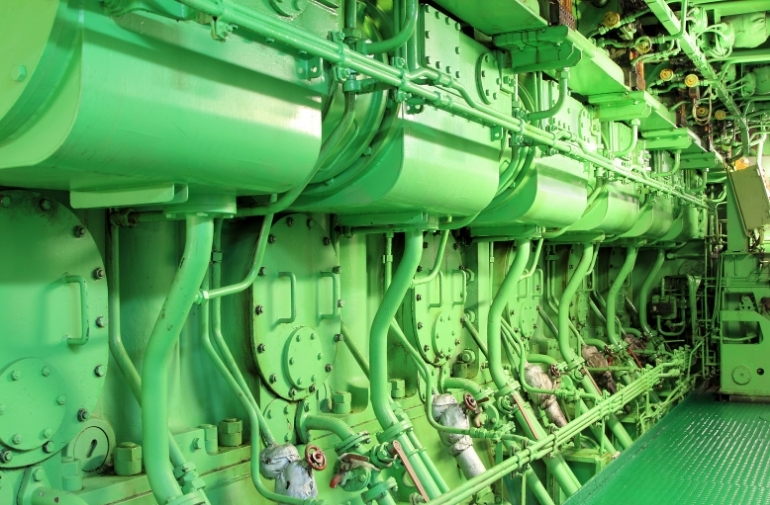

Marine engines are the backbone of any vessel, driving the ship through vast oceans while enduring intense operating conditions. For shipowners, maximizing the lifetime of these engines is not only a matter of financial prudence but also essential for maintaining operational efficiency and safety at sea. An engine failure at sea can result in costly repairs, significant downtime, and even dangerous situations for the crew and vessel. Therefore, adopting a strategic approach to marine engine maintenance is critical in ensuring that engines run smoothly and reliably for years.

One of the most effective ways to extend the lifetime of marine engines is through regular maintenance. This involves adhering to a strict schedule of inspections, tune-ups, and servicing. Each engine component, from pistons and bearings to valves and filters, requires attention to prevent wear and tear that could lead to larger problems. Routine checks allow engineers to detect potential issues early on, whether it's an oil leak or a slight decrease in performance, and address them before they cause extensive damage. By consistently monitoring engine performance, shipowners can ensure that their vessels remain in peak operating condition.

Key aspects of engine maintenance include proper lubrication and the care of the cooling system. Lubrication is essential for reducing friction between moving parts, which helps prevent wear and prolongs the life of the engine. Ensuring that the engine's lubricants are clean and topped up is a fundamental aspect of routine maintenance. On the other hand, the cooling system prevents the engine from overheating. Overheating is one of the most common causes of engine failure, so keeping the cooling system in top condition is critical. This involves regularly checking the coolant levels, inspecting hoses for leaks, and ensuring the cooling fans are functioning properly.

Another vital part of extending the lifetime of marine engines is the ability to detect early signs of wear and tear. By monitoring engine performance data, such as fuel consumption, engine temperature, and vibration levels, engineers can spot unusual trends that may indicate an underlying problem. For instance, an increase in engine temperature could signal a cooling system issue, while abnormal vibrations might suggest a misalignment or imbalance in the engine’s internal components. Early detection of these signs allows for prompt intervention, which can prevent small issues from escalating into major failures.

One of the most significant benefits of following a strict maintenance schedule is the reduction of downtime and repair costs. Marine engines are complex systems, and neglecting routine maintenance can lead to serious issues that require expensive repairs or even complete engine overhauls. These repairs can take a ship out of service for extended periods, causing delays in shipping schedules and revenue loss for shipowners. On the contrary, staying on top of regular maintenance can minimize the risk of sudden breakdowns, keeping the vessel operational and reducing the need for emergency repairs.

Fuel management is another critical factor that plays a role in engine longevity. The quality of the fuel used in marine engines has a direct impact on their performance and lifetime. Contaminated or poor-quality fuel can cause clogs in the fuel injectors, reduce engine efficiency, and increase the risk of damage to internal components. Therefore, shipowners must ensure that they source high-quality fuel and use proper fuel filtration systems to remove impurities. Additionally, monitoring fuel consumption and making adjustments to optimize fuel efficiency can reduce the strain on the engine, contributing to its long-term health.

Finally, insights from marine engine experts can provide valuable tips on maintaining engine longevity. Industry professionals emphasize the importance of thorough training for engineers and crew members who are responsible for engine care. Properly trained personnel are more likely to detect issues early and carry out maintenance tasks correctly, ensuring that engines continue to operate smoothly for years. Experts also recommend investing in quality replacement parts when needed, as using substandard components can compromise engine performance. By combining expert knowledge, best practices, and a diligent maintenance schedule, shipowners can significantly extend the lifetime of their marine engines, ensuring reliability and cost-efficiency.

Leave A Message